Indicators on Premier Aluminum Llc You Should Know

Table of ContentsThe Basic Principles Of Premier Aluminum Llc The Buzz on Premier Aluminum Llc6 Easy Facts About Premier Aluminum Llc DescribedPremier Aluminum Llc Can Be Fun For Everyone

(https://letterboxd.com/premieraluminum/)Generally, a buyer's main responsibility was to find qualified and responsive providers. Sometimes, purchasers assumed that any type of distributor ready to contractually fulfill the purchase requirement was certified. Nonetheless, making use of affordable and unqualified suppliers can cause high quality concerns, and lost time and money over time. To assist you through the process, below are some things to take into consideration when choosing the right steel spreading vendor.

For instance, a business that just utilizes the financial investment spreading procedure will certainly try to market you on why that procedure is best for your application. However what happens if utilizing the sand casting process is best for you and your demands? Instead, look for a supplier that uses a variety of casting processes so the finest option for YOU is picked

If collaborating with a single resource for every one of your casting requires is necessary to you, the supplier requires to be varied in its abilities. When combined with other incorporated abilities, this can aid simplify and compress the supply base. When picking the best casting vendor, careful factor to consider must be provided to high quality, solution, and price.

The Basic Principles Of Premier Aluminum Llc

Customers progressively pick spreading distributors that have machining abilities. This can stay clear of dispute if flaws are uncovered during machining. If a 3rd party is machining, it may cause "finger-pointing" regarding that is at fault. Is it a spreading problem or a machining issue? If the spreading provider uncovers a problem throughout machining, the problem is solved quicker without disagreement over whose fault it is.

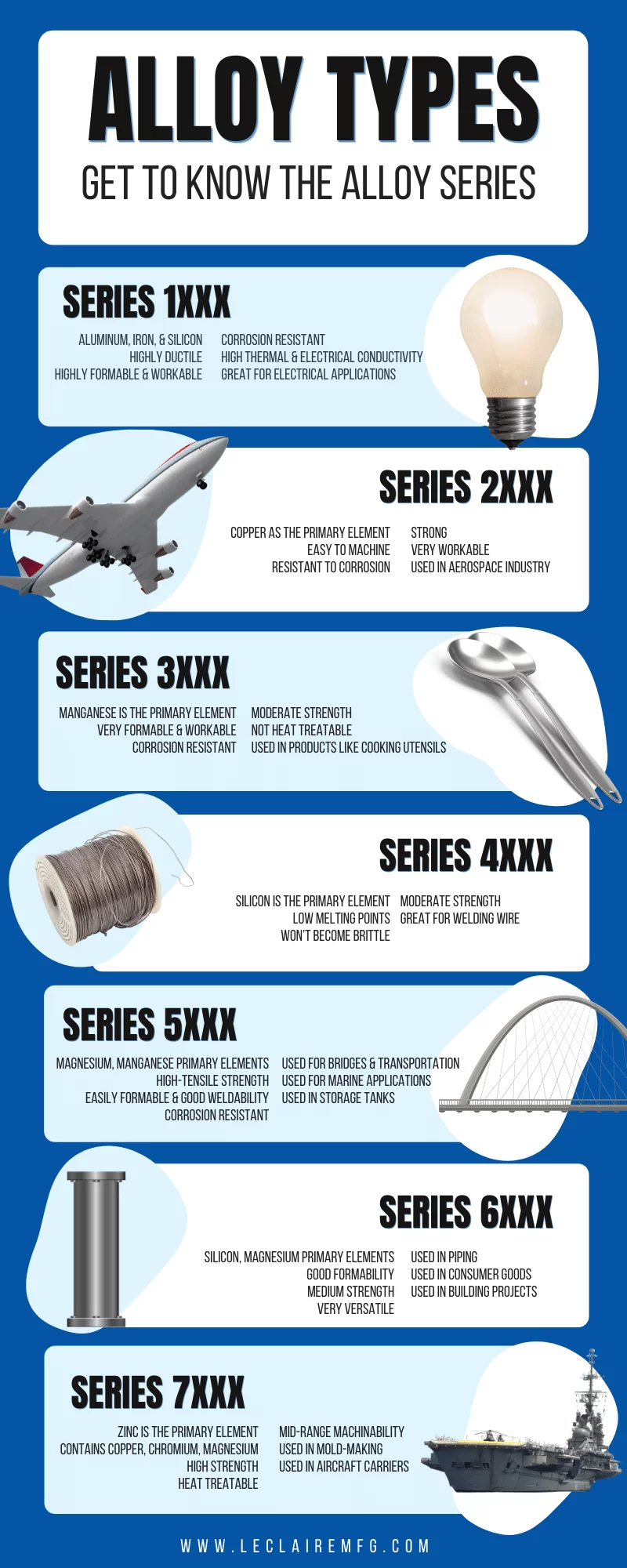

Problem or no, incorporated machining simplifies the supply chain and decreases taking care of time and delivery cost prior to the product makes it to the consumer. What do you need from your spreading provider? Are you trying to find somebody to simply supply a steel part to your doorstep or do you require much more? As an example, if you do not have in-house metallurgy knowledge, verify that the distributor can offer support in picking the proper alloy based on your specific application - Foundries in Wisconsin.

Others will certainly exceed the letter of the PO to help you save money and time. Do you have demands for both ferrous and non-ferrous alloys? Some factories are restricted or specialized. See to it the vendor can satisfy all your product or alloy demands to remove the requirement for multiple vendors.

The Definitive Guide to Premier Aluminum Llc

Research study the vendor's site. Talk to a sales rep or business partner.

Aluminum is also light-weight and has great rust resistance, making it suitable for applications where weight and toughness are very important variables. In addition, aluminum spreading is an affordable approach of manufacturing, as it calls for much less power and resources than various other techniques. Iron spreading, on the various look at here now other hand, includes putting liquified iron into a mold to create a wanted form.

The Ultimate Guide To Premier Aluminum Llc

Iron casting is additionally able to hold up against heats, making it appropriate for use in applications such as engine components and industrial equipment. Nonetheless, iron casting can be a lot more pricey than light weight aluminum spreading because of the greater expense of resources and the energy called for to melt the iron. When determining in between light weight aluminum spreading and iron casting, it is important to take into consideration the particular requirements of the application.

In final thought, both light weight aluminum spreading and iron spreading have their very own special benefits and negative aspects. There are 3 sub-processes that fall under the category of die casting: gravity die casting (or permanent mold casting), low-pressure die casting and high-pressure die casting. To get to the finished item, there are 3 primary alloys made use of as die casting product to pick from: zinc, light weight aluminum and magnesium.